Ginhong manufactures top-quality Carbopol Mixers for the cosmetic and pharmaceutical industries. If you want to leverage your production line’s capability in producing lotions, hand sanitizer gels, cosmetic creams and other water soluble gel products, you need high shear Carbopol mixers made by a professional manufacturer.

If you have a pharmaceutical manufacturing industry, surely, you have encountered rheology modifiers such as Carbopol. Carbopol is a white, fluffy and dusty powder usually needed in making gels in personal care and cosmetic products.

As its purpose is to be a thickener, stabilizer, emulsifier for suspensions, it must require industrially capable manufacturing equipment. These are mixing equipment which can handle high viscosities of up to 30,000 to 60,000 cP of suspensions.

At a low percentage in the formulation, the gel formed has a slippery feature like in antibacterial gels. When it is required at high concentrations, it forms a high viscosity gel like a pseudoplastic. Only at high shear force of a pump or mixer can its viscosity be reduced.

Fortunately, Ginhong high shear mixers can efficiently solubilize, homogenize, disintegrate and emulsify preparations with Carbopol ingredients.

Particulate powders, like Carbopol polymers and other rheology modifiers, can form clumps when not properly incorporated and mixed with the solvent. With our expertise in manufacturing high shear mixers for Carbopol gel formulations, you get the high quality mixture you need to promote your skin care product.

Ease of Powder Incorporation with Consistent Mixing Quality

Our industrial-grade Carbopol mixer is designed for rapid incorporation of powders, fast mixing time and efficient dispersion of ingredients. You can choose between our high shear mixer, multi-shaft mixer and vacuum emulsifier mixer to better suit your ingredient requirements and special needs in mixing parameters.

Tailored High Quality Mixer to Meet Your Gelling Agent Formulation Requirements

At Ginhong, we can customize your mixing equipment to meet your requirements and budget. Our mixers are tailor-made for each client whether it’s needed for a pharmaceutical, cosmetic or food industry. You can request for automated PLC controls, or an additional powder feeder depending on what you need. This ensures a more suitable system for efficient mixing, variable throughput, seamless operation and quick changeover.

Reduced Production Costs, Increased ROI

With high energy mixing and rapid powder incorporation, you can assure that the mixtures result in agglomerate-free gels. Our mixers can fully hydrate powders. This allows you to reduce on raw material wastage and additional processing equipment, ultimately reducing your production costs! At the end of the day, your production ROI is increased.

Ginhong’s High Shear Mixer has ruggedized features a cosmetic manufacturer would adequately need. It is highly efficient in making emulsified solutions of hand sanitizers, cosmetic products and other personal care products. Having the capability to homogenize, disintegrate and emulsify solutions at fast inherent reaction rates, you can seamlessly produce consistent batches of gels.

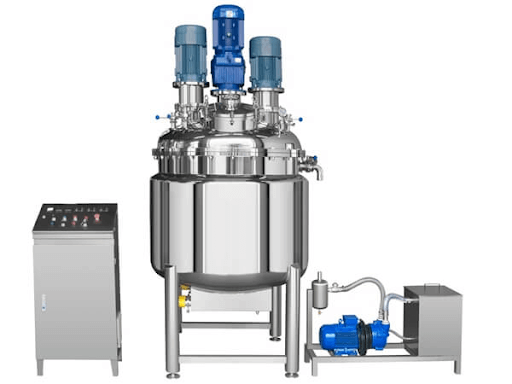

Ginhong’s High Shear Mixer can process bulk carbomer powders and thickeners at maximized output. We have it equipped with a high speed disperser, agitator and a rotor-stator homogenizer, precision-made for properly mixing ingredients. It can also have a stainless steel mixing tank having a capacity from 100L to 300L.

Ginhong High Shear Mixers:

Ginhong’s Multi-Shaft Mixer is ideally used in processing batch and continuous mixtures of high viscosity gels. It has two to three mixing shafts working in tandem, as they blend, emulsify and homogenize products. It has an agitator stirrer/scraper, a homogenizer and an addition of two or more dispersers.

It’s high energy can handle Carbopols and other carbomer formulations with up to 80,000 to 100,000 cps of viscosity. We carry affordable Multi-Shaft Mixers, highly customizable, to fit your specific recipe needs.

Ginhong Multi-Shaft Mixers:

Our Vacuum Homogenizer Mixer is a complete, vacuum-filled system which homogenizes, emulsifies and disintegrates materials, while operating in a clean-in-place environment. It can be incorporated with two separate tanks which can be used for the oil phase and water phase mixing. To facilitate sanitary mixing, all contact parts are made from stainless steel.

In addition, processing in vacuum helps prevent bacterial growth in the mixing tank and eases the transport of powders along the pipes.

Vacuum Emulsifier Homogenizer

Ginhong’s High Shear Bottom Entry Mixers can be used in conjunction with a slow anchor agitator for processing thick gel formulations. It has its rotor-stator homogenizer arranged at the bottom of the mixing tank.

DX Bottom Entry Homogenizer

To manufacture an effective and good quality hand sanitiser gel, spray, liquid or foam solution, the FDA and WHO released guidelines to be followed. These include compounding procedures for alcohol-based hand sanitizer to meet pharmaceutical standards.

The key to making foam hand sanitizer used in hospitals or for routine consumer use is to make it with at least 60% v/v alcohol. This can inactivate Covid-19 or other germs on the hands when applied correctly.

However, there are also formulations which are non-alcohol. Non-alcohol hand sanitizers, on the other hand, cannot kill Coronavirus.

Basic ingredients of hand sanitizers may include an active ingredient, which is alcohol or non-alcohol ingredient. Additional ingredients include glycerol, and hydrogen peroxide.

The WHO recommends alcohol-based formulations as it is effective, tolerable and cost-effective for providing bulk hand rubs for healthcare settings. Sanitizing ingredients may be Ethyl or Isopropyl alcohol at very high concentrations of about 96%. When blended with water and other ingredients, the final alcohol content should be between 60 to 90%.

But in general, the formulation can vary with different ingredients. Here are the basic ingredients for non-alcohol and alcohol-based hand sanitizers.

Here’s an example of an alcohol-based herbal hand sanitizer formulation from Research Gate.

| Component | Viscosity | Purpose | Percentage |

|---|---|---|---|

| Ethyl Alcohol/Isopropyl Alcohol | 10.95× 10-4 Pa-s | Active ingredient/antibacterial | 62% |

| Water | 7.98 × 10-4 Pa-s | Solvent | 30% |

| Glycerine | 0.950 | Emollient | 2.3% |

| Peppermint extract | - | Antibacterial | 1.5% |

| Neem leaves extract | - | Antimicrobial | 1% |

| Triethanolamine | Miscible in water | Solubilizing agent; to prevent skin irritation | 0.7% |

| Carbopol (Carbomer) | 40-60 Pa-s | Thickening agent to make gel or emulsion; for stabilizing the solution | 0.5% |

| Clove oil | - | Antibacterial | 0.5% |

| Polysorbate | 0.375 | Emulsifier | 0.5% |

| Perfume | - | Fragrance | 0.5% |

| Preservative | - | Preservative | 0.5% |

Some formulations also add bitter tasting compounds to discourage people from drinking hand sanitizers. This is usually added to the alcohol as denaturants to make it taste bitter for children to eat.

| Component | Purpose | Percentage |

|---|---|---|

| Benzalkonium Chloride | Antimicrobial agent/active ingredient | 0.2 |

| Surfactant | Cleaning and spreading agent | 1 |

| Humectants | Moisturizer | 4 |

| Thickener | Increase viscosity/define consistency | 0.3 |

| Fragrance | Aesthetic | 0.4 |

| Bitter-tasting compound | To prevent people from consuming the product | 0.12 |

| Preservative | Preserve the life of hand sanitizer | 0.1 |

| Water | Solvent | 93.88 |

Hand Sanitizer Gel

Usually 75% Ethanol or Isopropyl solutions with a main ingredient of deionized water, alcohol, and gel moisturizer, emollient.

Foaming Hand Sanitizer

Composed of deionized/distilled water, surfactant, foaming agents, moisturizing agents, and disinfectants.

The different viscosities of the ingredients means the mixer would have to bear different physical properties of the materials. During the mixing process, there should be a powerful action in an industrial blender to achieve a uniform agglomerate-free and consistent batch-to-batch mixtures.

The mixing process is as follows:

When manufacturing hand sanitizers a number of problems may be encountered:

Ginhong’s High Shear Mixer and Multi Shaft Mixer are equipped with the latest components for seamlessly processing hand sanitizer ingredients. These robust industrial blenders have control panels, homogenizer, pneumatic lifting mechanism and motors. Stainless steel pipes, filters and valves can process the solution at a clean, and rust-free environment.

Ginhong’s Hand Sanitizer Mixer has a number of advantages:

When using a traditional agitator, mixing Carbopol in a water solution may be more difficult. For one, the powders may only float in water without proper agitation and good vortex.

Oftentimes, a high pH ingredient must be added to the solution so that the final viscosity will not be too low. Carbomers are not really soluble in water, but they do form into hydrated spheres, giving your product its rheological properties. In terms of gum formulations, Carbopol may form agglomerates as well, when not properly mixed.

A powerful industry mixer is used in diluting thickened solutions in large scale production to achieve homogenized mixtures.

Carbopol® is a carbomer that is a registered trademark under the Lubrizol Corporation. There are different Carbopol polymers available under the company which are either synthesized in a cosolvent mixture of cyclohexane and ethyl acetate or ethyl acetate.

As such, depending on what type of Carbopol you use, it may have different resulting viscosities in your formulation.

|

Carbopol Polymer |

Viscosity, cP (0.5 wt% at pH 7.5) |

| 71G NF | 4,000 - 11,000 |

| 971P NF | 4,000 - 11,000 |

| 974P NF | 29,400 - 39,400 |

| 980 NF | 40,000 - 60,000 |

| 981 NF | 4,000 - 10,000 |

| 5984 EP | 30,500 - 39,400 |

| ETD 2020 NF | 47,000 - 77,0002 |

| Ultrez 10 NF | 45,000 - 65,000 |

| 934 NF | 30,500 - 39,400 |

| 934P NF | 29,400 - 39,400 |

| 940 NF | 40,000 - 60,000 |

| 941 NF | 4,000 - 10,000 |

| 1342 NF | 9,500 - 26,500 |

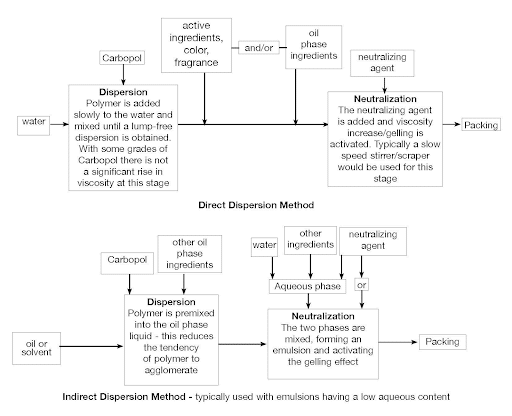

Here’s a sample illustration of how Carbopol is mixed in skincare/pharmaceutical manufacturing:

Ginhong industry-grade mixers accomplish the production of Carbopol formulations through the following simplified methods using a top entry batch mixer:

For the Neutralization Process:

Ginhong mixers can also be used for neutralizing Carbopols, depending on the viscosity of the product. For processing very viscous products, a low shear agitator can be used.

Ginhong is a leading manufacturer and supplier of industrial mixers for Carbopol gel formulations. Our industry grade mixers can process different rheology modifier thickeners with the following advantages: